The van’s previous owner left me a trash bag of documents. An expired warranty for tires. A receipt for an oil change completed in 2013. An operator’s manual for a truck refrigeration unit.

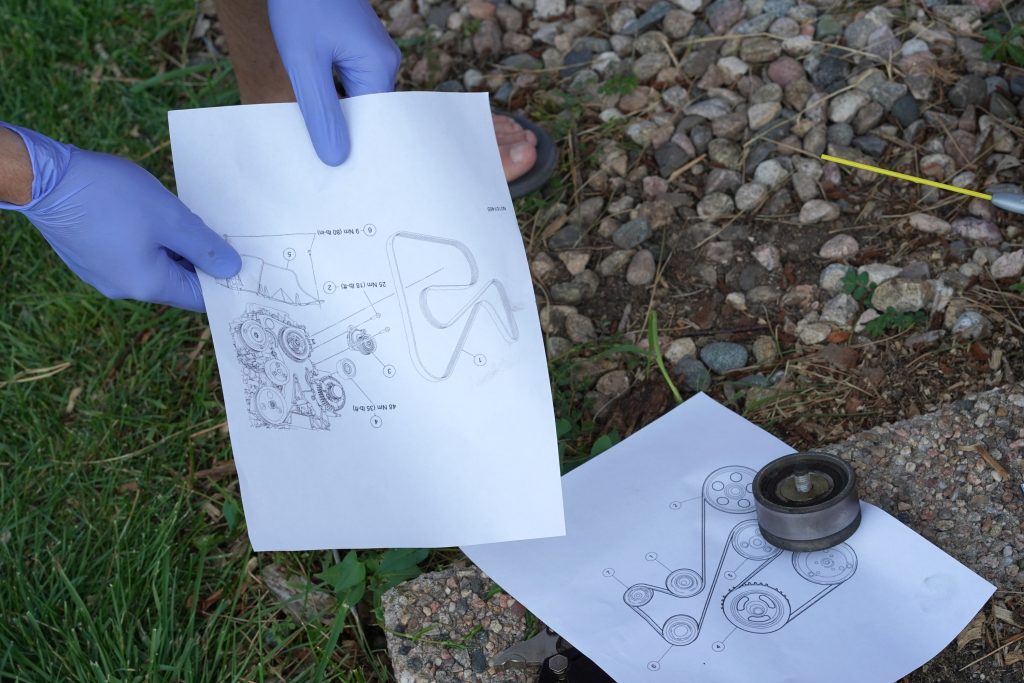

I was about to chuck the refrigeration manual with the rest of the bag’s contents when I realized its importance: My van used to be refrigerated. Probably two owners ago. This explained everything. Why did the van have circular holes in its roof and undercarriage? For pipes leading to the refrigeration unit. Why did its floor have surface rust? Condensation, a result of temperature fluctuation. Why did the engine squeak? Someone had added a big compressor (what Kevin is holding up in the photo above) and three extra pulleys to the accessory belt system. They’d elongated the belt but kept Ford’s original belt tensioner, which wasn’t made to pull so much belt. So the tensioner wore out, leading me to a repair shop in rural Texas. Even with a new tensioner, the belt system continued to squeak, because Ford’s tensioner was never meant for such a big job. Squeak, squeak, squeak. Every time I started the van, a hamster on a fitness kick settled in behind my right temple, and that fucker made sure to bring his wheel.

To stop the squeaking, the compressor and extra pulleys had to be removed, and a new, smaller belt put in. A friend, Kevin, kindly offered to help. He estimated it’d take two hours. We met at 10am one Sunday. We figured we’d have plenty of time to finish the job before the afternoon rain rolled in.

The job took 19 hours over the course of two days.

We encountered difficulties. One of the brackets holding up the engine needed to be unbolted, and the engine held up on a jack. The compressor wouldn’t come out because of a bolt that protruded into its space. The tensioner wouldn’t un-tension all the way. It rained. Kevin bled three times. I bled once, while cutting a lime. We drank mojitos. The new belt would not fit, no matter how long we laid it out in the sun to soften, or how determinedly I blow-dried it on the hottest setting in the bathroom. Just after Mike offered to blast the belt with his heat gun, he noticed that one of the pulleys we were trying to wrap the belt around did not look like the others. It was slightly too big and looked too much like the pulleys we’d removed. We needed to replace this pulley with Ford’s original pulley. We bought the replacement pulley; slipped the new belt on; re-bolted the engine bracket, fluid reservoir, and plastic flange; reattached the tire we’d removed to access the tensioner; and celebrated a job well done.

Then we realized we had one bolt left, and no one knew where it went. There was a good chance the errant bolt belonged to the compressor or pulleys we’d removed. There was a tiny chance that it was an essential part of the van.

I don’t think you need a Myers-Briggs test to figure out your personality type. It’s in little moments like this one, the case of the leftover bolt, that personalities truly come out.

Leftover Bolt: A Personality Quiz / Psychological Indicator / Introspective Self-Report Questionnaire

After 19 hours of mechanical work, you find a bolt of unknown origin. What do you do?

- Fuck it, just start the van, because you’re late to an archery hang. “You have to take risks. No risk. No return. Go get it.” —ExtraMadness Tumblr

- Suggest several places where the bolt might belong, and when none of these pan out, cheerfully text, “hey if we can’t remember that’s just less weight right?!”

- Take the van apart again and re-inspect everything.

#3 is what Mike ended up doing by himself, while I left to shoot arrows at fake turkeys. (At this point Kevin was back at his place, because friends don’t let friends work on their cars for more than 19 hours.)

In the end, Mike did not find a place for the bolt, and the van started up just fine without it. No squeaking! But Mike’s inspection still served a purpose. While putting everything back together again, he noticed two electrical wires touching the exhaust manifold (which gets very hot) and repositioned the wires with zip-ties so they wouldn’t burn.

For integrity’s sake, I should note that we did not actually do any mechanical work for 7 of those 19 hours. During this time, Mike, Kevin, Kevin’s partner Dorna, and I played Codenames, ate an entire plum cake, and conducted a blind taste-test of six whiskeys (with predictable results; Johnnie Walker Red Label came in last).

I should also admit that I contributed very little to this project.

All the times I said “we” did something in the preceding paragraphs, it was really mostly Kevin and sometimes Mike. At one point I tried to get a rotary tool working. Sadly, I did not succeed. It annoys me that I have so little aptitude for mechanical work, and that my lack of automotive knowledge feeds a stereotype: I am that woman. Right now I am tempted to dive deep into gender and how it plays out in #vanlife, but I won’t because a) I’m saving up material for a future post, “A Woman Walks into a Mechanic’s Shop in Rural Texas” and b) I’m sleepy.

What I will say is that my helplessness during this step of the van build fueled my decision to build the van’s electrical system completely by myself. For the next couple days, it’ll just be me, my van, three boxes of electrical parts, Youtube, and a pot of pre-cooked pasta and sausages. I know that power = current x voltage. I know that, if I don’t get the various fuses and wire gauges right, I could start a fire. I also know that, if I connect the solar panels to the battery and charge controller in the wrong orientation, the 120-pound battery might explode. Let’s do this. And by that I mean, let me do this.